Daisuke Yamamoto

The Tokyo-Based Architect Changing Perspectives on Building Materials and their Value

Based in Tokyo, architect and designer Daisuke Yamamoto is a problem solver. All great designers are, they provide solutions for the modern times we live in.

As an architect and designer, Daisuke is exposed firsthand to the continuous single-use of materials in building construction. Graduating in Architecture at Musashino Art University in Tokyo, Daisuke then worked at WONDERWALL (by architect Masamichi Katayama), going on to found his own studio DAISUKE YAMAMOTO DESIGN STUDIO.

Growing up in Tokyo’s man-made town called Yume-no-shima (also known as the ‘Island of Dreams’), the area is created from a landfill site where industrial waste was once disposed. As a child, Daisuke learned about how waste has become an industry, and how to design it out of our lives.

Through his design company, DAISUKE YAMAMOTO DESIGN STUDIO, he worked on a collection that would highlight and emphasise the most easily re-recycled – yet the most discarded – material in the building industry: LGS, also known as Lightweight Gauge Steel.

Looking at solutions to fix the large-scale problem in the building industry of material single use and waste, Daisuke developed the FLOW collection entirely made of repurposed LGS steel – shockingly still the most used and discarded material in the building industry. With a light coating of zinc, LGS does not rust, and can be re-recycled endless amounts of times.

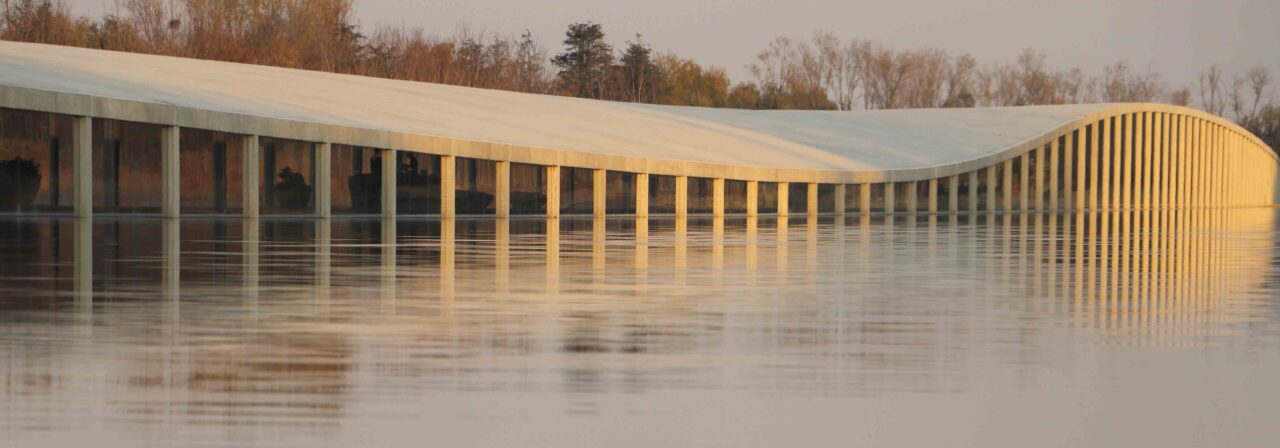

Daisuke’s first furniture collection FLOW, sees a series of chairs, stool and table. The designs are able to be reconfigured and reconstructed to a different design at any time, highlighting the re-use of the material, creating a sustainable, circular flow. Debuting the FLOW collection at his FUTURE LANDFILL exhibition at DROPCITY (founded by architect Andrea Caputo) during Milan Design Week 2023, Daisuke’s designs were received with high acclaim.

Now, Daisuke has also been tapped by the LGS manufacturer in Japan to design sustainable emergency housing for those affected by earthquakes in the country, utilising his ideas for circular design for temporary shelter design that can be constructed and de-constructed multiple times as needed.

With his work creating strong solutions in design, architecture and changing general perspectives in both industries on material single-use, we see a strong career trajectory for Daisuke. We needed to know more about FLOW and his next moves, so we spoke to the designer about his practise and architectural training that has influenced it.

CHAMP: Through your work as an architect, you saw that construction materials often go directly to waste and aren’t re-recycled. Can you tell us more about the lightweight steel that you’re now utilising in your work?

Daisuke Yamamoto: LGSは主に建物の内側の壁や天井の構造材として最もポピュラーに使われているマテリアルです。日本では古来より木造で建築を建てる習慣がありました。近代になるにつれ木材より素材強度の観点や木材の伸縮性の問題を解決するため安定性が高いかつ不燃性が重要視され多くの建物内側を形成する構造材として使用されています。特に商業空間におけるLGSの使用されていない現場を見ることがないほど標準使用で膨大に使われています。日本における商業空間の平均寿命は3~5年と統計が出ており、非常に早いサイクルで新しい資材でつくり壊し廃棄されている素材の一つといえます。

LGS is the most popular material used primarily as a structural material for the interior walls and ceilings of buildings. From ancient times in Japan, it has been the custom to build buildings with wood. With the rapid economic growth, nowadays it has been replaced with LGS to form the interior of many buildings because of its high stability and non-combustibility, which is more important in terms of material strength and also to solve the expansion and contraction of wood.

LGS is so widely used as a standard material that it is hard to find a site without it, especially in commercial spaces. There are statistics that say that the average lifespan of commercial spaces in Japan is 3-5 years, a so called “scrap and build” environment. From this background, we can say that LGS is one of the most used materials in construction that are being used in a very fast cycle, at the same time demolished, and disposed despite their durability and longevity as a material.

Exhibiting your ‘FLOW’ collection of chairs and tables during MILAN DESIGN WEEK 2023, can you tell us more about your concept and your process of exhibiting your works in Milan? Were they made in Tokyo or on-site in Milan?

ミラノで展示するにあたり私たちは 「FUTURE LANDFILL」というコンセプトを掲げています。

FLOWの製作プロセスは空間に使用された本来であれば廃棄されるLGSを解体現場でビスを外し解体し、材料に戻し、家具やプロダクトに再構築することから生まれます。つまり解体現場は使用の終わった資材が廃棄へと向かう最初の廃棄処理施設となります。その処理施設は本来であれば廃棄へと向かう場所となるはずですが、私たち建築家やデザイナーがその廃棄処理施設に介入し、素材の解体方法や素材を廃棄せずに使用する方法を創造的でラテラルな思考を持ち産業廃棄物の発生を止め、使用済みの素材を新たな意味を持って活用する再考の場をコンセプトに掲げました。目的は現代社会における廃棄物の扱い方のメカニズムについて、疑問やフィードバックを提供し議論を活性化させることです。

大量消費は「考える→作る→廃棄する」という形で処理されるのが一般的ですが、持続可能な社会を実現するために私たちは「廃棄→思考→再創造」というアプローチをとっています。デザインに「再創造」という機能を加えることで、新たな資源の循環を構想することができるのです。この再組立スタジオ「FUTURE LANDFILL」は無限の可能性を秘めた場所であり、私たちの未来を考える上で創造的な思考を促す最も重要な場所となり得ると信じています。

ミラノでは現地でLGSの廃棄パネルを椅子やテーブルに再構築するプロセスを実際に行い、展示にお越しになる方々に見ていただくようにしました。

The concept of our exhibition in Milan was “FUTURE LANDFILL”.

FLOW’s production process is based on the process of removing screws and disassembling LGS used in a space that would normally be disposed at a disassembly site, rather recovering them to their original state, then reconstructing them into beautifully redesigned furniture and products. This means demolition site is the first disposal facility where used materials are disposed. In this situation, we architects and designers intentionally intervene in this waste facility = demolition site with creative and lateral thinking on how to reuse these materials that were bound to be disposed and abandoned, brought back to life. It is a place to reimagine, to stop creating industrial waste, rather, fully utilize these used materials with new meaning. Our mission for the “FUTURE LANDFILL” was to provide questions and feedbacks while activating discussions around the mechanism of how we deal with disposed materials in our modern society.

Mass consumptions are usually processed in the form of “think -> build -> waste”. However, in order to realize a sustainable society, we take an approach forward; “waste -> think -> re-create”. By integrating this additional feature to the design process, to “re-create”, allows us to envision a new circulation of resources. We believe this re-assemble studio “Future Landfill” unfolds infinite possibilities and could be the most important place to empower and reflect our creative thinking towards our consideration for our future.

During the exhibition in Milan, we showed the process and reconstructed discarded LGS panels into chairs and tables at the site for visitors and everyone to see.

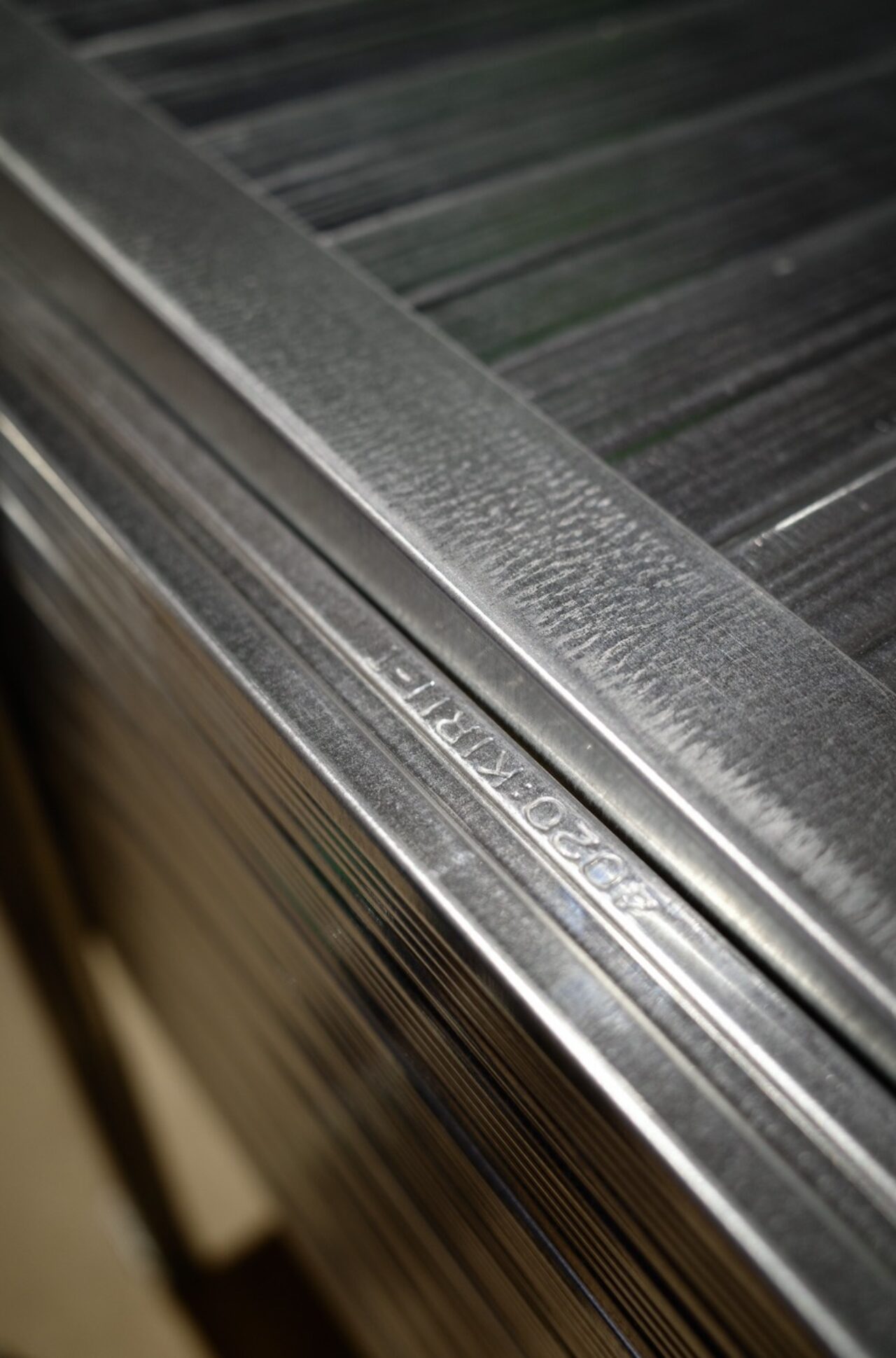

You use a particular sizing of LGS. Can you tell us more about this?

日本では古来より木造で建築をつくる仕組みがあり、それにとって変わり高度成長期あたりから木の伸縮を安定させることや防火性を考慮されLGSが頻繁に使われるようになりました。そのためLGSも規格は木材の規格と同様のサイズバリーションがあります。その中で私たちが今回用いたのは、家具へ再構築をすることを前提に□20×40のサイズのLGSを用いて空間をづくりをしています。私たちは設計する段階で解体されることを視野に入れて計画しています。他のサイズも使用していますがそちらも事前に解体時にどのようなものへ再構築するかを決めてから空間設計するようにしており、テーブルやパーテションが実際に出来上がっています。

In Japan, wood was the common material used in building structures since ancient times, however, LGS are now more frequently used since the period of rapid economic growth and also because of its high stability and non-combustibility. Therefore, LGS has the same size variations as wood standard in Japan.

For this project, we used LGS of 20 x 40mm. Our design approach is a reverse process where we designed and construct space with the assumption that they will be deconstructed, then redesigned into furniture after disassembly. That is why we used this size since they are suited for making chairs. We also used other sizes in this space that were reconstructed to tables and partitions, of which were also planned advance at design stage.

LGS is most commonly used in the build of any interior wall structure. Is the LGS you work with on your chair and tables designs already re-purposed from building sites?

はい。今回ミラノ展示した椅子やパネルは自分達で設計した空間の資材を再利用して製作されています。

Yes, the chairs and panels exhibited in Milan were made by reusing materials from spaces we designed.

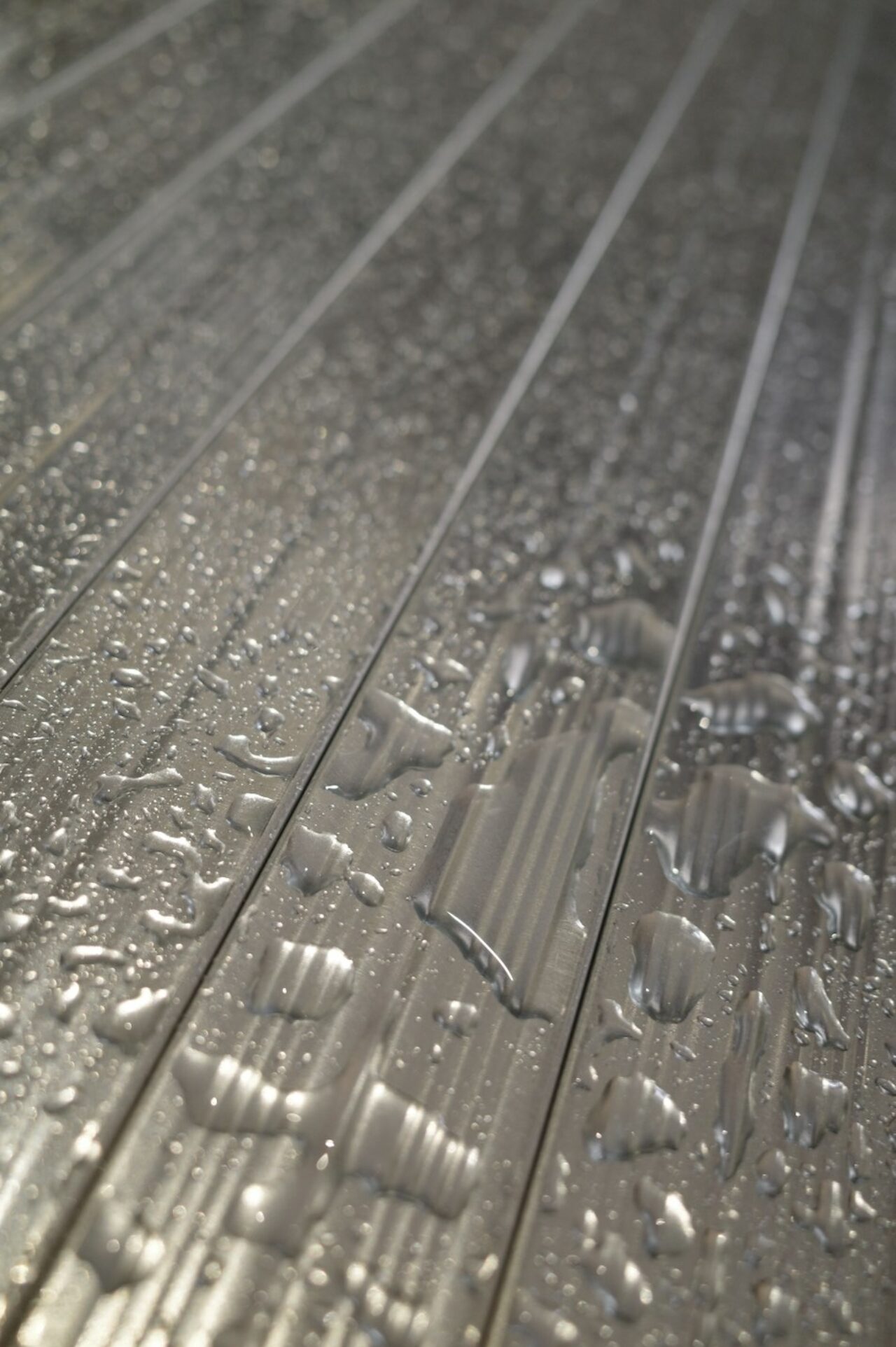

You’ve mentioned that because the LGS steel is zinc coated, it doesn’t rust and can be re-recycled. How many times?

はい。スチールの防錆·防腐食として亜鉛メッキが施されています。

この建築資材が建築の構造材として性能を保持する最低対応年数は一般的に20年~30年と言われており、建築の構造材である鉄骨の対応年数とほぼ同等対応年数も持っています。もちろんその期間を過ぎても使用することも可能であると製造メーカーからお伺いしています。資材を使い続けるようにするために解体時にいかに材料を戻すことができるのかが大切なポイントなのではないかと考えています。

Yes. LGS is galvanized with zinc to prevent rust and bar corrosion.

It is said that the minimum life span for building material to retain its performance as a structural material for construction is generally 20 to 30 years, which is almost the same as the life cycle of steel frames, which are structural materials for construction. However, we have been told by the manufacturer that it is possible to use the material even longer after that period. We believe the important point is how these durable materials can be returned to their original state at the time of demolition so they can be reused and reclaimed.

As an architect and designer, how do you see your work traverse these two fields?

私にとってはすごく自然な成り立ちを持っています。

建築家としてデザイナーとして最も大事にしていることは、豊かな社会を目指し、今デザインに何が可能なのかを問い詰めることにあり、デザインは人と社会を繋げる役割を担っていると信じています。そのような意味において、建築におけるこれまでのつくることをゴール地点としていたプロセスを見直し環境のことを考え廃棄される地点から考え直すことと、その素材の循環を考え椅子などのプロダクトへ再構築する行為は別々のことではなく、一つの豊かさへの可能性を問いかけるデザインであり、人と社会を繋げる役割を担っていると思います。

I think it is a natural connection for me. As an architect and designer, what I value most is to continue to question with the intention that it will breakthrough solutions and activate dialogue towards anticipating problems in hopes to enrich and reshape our possible future. In this sense, reconsidering the process of architecture where the goal is not just to create but to create from the point of disposal in mind, and reconstructing chairs and products by rethinking material circulation is the same, addressing the same message of rethinking about what designing for people and the society truly means. I believe both design and architect play a role in connecting to enrich people and the society to the fullest.

You’ve mentioned you are working on a project with the lightweight gauge steel production company. We think that it combines both your architecture and design work! Can you tell us more?

私達は今ある資源をどのように活用するべきなのかという考えを持ち、未来を見据えています。

今僕たちが取り組んでいるプロジェクトは、産業が発展した社会背景のひとつに分業化にしていくことでより効率的に生産をする産業システムとそのプロセスから出来上がった建築資材や部品を集め、それらをアッセンブルする中に生まれる歪みに注目しています。つまり建築資材を集め、いかに組み立てるのかという問題、そしてそのアッセンブルしたものをどのように廃棄するのかという問題です。その一つの解決策として、製造者側に立ちアッセンブルの仕組みやマテリアルの循環をつくることの可能性を感じています。

資材を開発·製造·販売する際に必ずリサイクルできることが求められ、製造側でもリサイクルする方法を持っていますが、実際にはまだ対応年数を満たしていない資材を建設現場で解体され解体業者が廃棄するので彼らの手元に戻ってくる資材はほとんどありません。

私たちが資材をどう活用すれば、回収できるようになるのか、または再活用できる仕組みをつくることができるのかという新たな視点を共同に持つことができれば、今実装している仕組みとは異なる社会へ開いていくことが可能なのではないかと感じています。そういう意味では建築とデザインの両方が結束する帰結点となる活動で、人·環境と社会を繋ぐ掛け渡しになる実践をできる場であると考えています。

Our activities are based on the idea of how we should utilize existing resources with consideration for our future. Current projects focus on the distortion created in the process of materials manufactured, gathered, and assembled as a result of the system centered around efficiency and development of the industry. In other words, the issue is how to collect the materials and how to assemble them, and how to dispose the assembled products.

As one of the solutions, we feel there are possibilities to stand on the manufacturer side to create a mechanism for assembling and designing circulation of materials. It has become a norm when developing, manufacturing, or selling, it is always required that they be recyclable. Manufactures usually have their own recycling methods, however in reality, materials that have not even met their endurance period are dismantled at the construction sites and disposed. Only very few are returned to the manufacturer for recycle.

I feel that if we designers and manufacturers collaborate to develop a new perspective on how we can utilize materials, how we can collect and create a system that allows us to reuse and recreate, it will open so many possibilities to change the current structure in place. In this sense, I believe that this activity will be a point of connection and solution for both architecture and design to unite, and a place where we can bridge people, environment, and the society together.

You work with your partner Mariko Moritani and sculptor Taketo Ota for your live build presentations. Can you tell us about the importance of the right team to work with?

私は様々な視点を持った仲間と一緒に仕事をすることを大切にしています。

もちろんそれがクライアントである場合も同様です。今私たちの取り巻く環境は一つの要素で成り立ってはおらず、様々は要素が複合的に絡み関係し合い成り立っています。

一つの問題を取り上げた時に様々なレイヤーや視点で問い詰めていく必要があります。その時に一人の専門家の視点だけではなく、異なる専門性を持つ仲間との対話や行動が私に多くの気づきを与えてくれると共に私たちの活動がより多くの言語を持った開かれた言葉になると感じています。

I value working with colleagues who have a variety of perspectives. The same is true when I work with clients. The environment that surrounds us today is not made up of a single element, but a complex intertwining of various elements. That is why when we bring up an issue, it is necessary to question it from various layers and perspectives. I feel that having a dialogue and taking action not only from one expert’s point of view, but also with colleagues with different specialties give me a lot of insight and make our activities broaden.

What do you have coming up this year at the studio in Tokyo? Any goals for the future?

まずLGSの製作を行なっている企業オフィスの移転計画があります。これは僕が行なっている空間づくりを実際に彼らとリサーチ·開発と実装を目標に進んでいます。

それ以外には僕の通っていた大学の改修を手がけていたり、これまで同様にファッションブランドと様々な計画をしています。

FLOWは今私の目の前に起こっていることから社会への問題提起を作品に込めています。今後の目標はその可能性を詰めていくことで新しい豊かさに繋げていきたいと思っています。

また先日のミラノデザインウォークに参加した経験が大きいのですがこれまでは東京での活動がメインになっていましたが、世界の様々な文化背景の中で、自分の目で世界を理解しコンセプトやコンテクストを大事にしながら建築とデザインの領域を横断する活動を行なって行きたいと思っています。

I am currently working on designing the office of the company that makes the LGS I am using. I am also working with them on new development and research on material circulation which I hope to present in near future. Other projects include working on the renovation for my university I used to attend, as well as various projects with fashion brands.

Most importantly, I will continue to evolve “FLOW”. “FLOW” has raised awareness towards invisible stories hidden beneath the surface and these stories have become cues to my creative process, observing what has been taken for granted and retrace the underlying narrative. My goal for the future is to expand these possibilities in hopes to enrich and reshape our possible future.

My experience and participation in the Milan Design Week has definitely influenced and inspired me in many ways. Until now, my activities have been mainly in Tokyo, however, I would like to expand my horizon to the world valuing concepts and context while not forgetting to see with my own eyes and heart and continue to work across design and architecture from a unique perspective.

Tell us about Tokyo! How long have you lived there, and why do you choose to live and work there?

僕は生まれも育ちも東京、8代目の江戸っ子で、生まれてからずっと東京で暮らしています。東京にはなんでもあります。行きたい大学があり、デザインの勉強をしたい師匠のスタジオがありました。

東京はすごく刺激的な街で常に変化を続けています。その変化の中に私はユートピアとディストピアの相反する感情を抱いており、その混在する風景が私に多くのインスピレーションを与えてくれます。

I was born and raised in Tokyo and I am the 8th generation Edo child and have always lived in Tokyo ever since I was born. For me, Tokyo has everything. There was a university I wanted to go to and a design studio I wanted to study design from who I admire greatly. Tokyo is an extremely exciting city that is constantly changing. In this transformation, I feel a conflicting sense of utopia and dystopia, however, this mixed landscape gives me so many inspirations.

What are your favourite spots in the city?

“夢の島” 私が生まれ育った場所は、区の半分近くが埋立で造られています。その象徴的な場所が産業廃棄物を埋立てることできた夢の島という人工地帯です。小さな頃から社会の授業で自分の住む街について知ることはゴミをどう処分するのかという問題と一緒でした。この場所を訪れると東京の持つ儚さと絶望感を感じることができるすごく美しい場所です。

”渋谷駅” 渋谷に私のスタジオがあります。今渋谷は大きな開発によって毎日違う風景に変わり続けています。

昨日通った場所は次の日は変わり、行きたいところにいくのにどう辿り着くべきか悩む迷路との葛藤が日課になっています。もしかしたらこの風景を毎日眺めていたことが無意識にFLOWの誕生に結びついたのかもしれません。

“Island of Dreams” Where I was born and raised, almost half of the district is built on landfill. A symbolic place of this is the man-made town called “Yume-no-shima” = Island of Dreams, an area created from a landfill site where industrial waste are disposed. As a child, learning about where I grew up was about understanding how we dispose garbage and the issues surrounding them. When I visit this place, I feel a sense of instability and fragility at the same time utmost beauty in this impermanence. It is a very beautiful place.

“Shibuya Station” My studio is located in Shibuya. Shibuya is a city where the landscape and expressions are breathing every day, constantly changing its form every moment, undergoing constant development. The place I passed by yesterday will be different the next day. It is literally a maze and despite knowing this city since junior high school, I struggle to find my way everyday…! Perhaps the view of this chaotic landscape subconsciously influenced my creation of “FLOW”.

Images: As credited, Champ Magazine © and Masayuki Hayashi

Interview: Champ Editor-in-Chief Monique Kawecki

Translation: Mariko Moritani

For more in Tokyo, check here.

#champ_tokyo #champ_japan