FUTURE FOOD SYSTEM

"Imagine If We Could Solve the World’s Biggest Problems by Simply Changing the Way We Live"

Visionary Joost Bakker’s latest Greenhouse project iteration has been aptly titled Future Food System, continuing his on ongoing mission to highlight the importance and accessibility of a no-waste lifestyle.

Future Food System is his most complex project to date, but the concept is simple, “Imagine if we could solve the world’s biggest problems by simply changing the way we live”.

Joost, an internationally-renowned artist, designer and zero-waste advocate, has been a globally-recognised voice in the call to eradicate waste from our lives. Based in Australia, his work has inspired countless leaders in the industry, from London (informing the birth of the UK’s first zero-waste restaurant SILO by chef Douglas McMaster, a previous alumni of Joost’s) to New York (with no-waste chef Dan Barber stating “rarely I have met someone so preternaturally talented that he also changes the culture with his work”), his mission towards a zero-waste future has made it all the more possible.

A zero-waste lifestyle has been made even more accessible than ever before thanks to Joost’s ongoing work. We know that 1/3 of the world’s food supply is not even eaten, it is food waste. Through simple, sustainable design solutions, we can better the world around us and secure our collective future. The Greenhouse is this ethos put into practise.

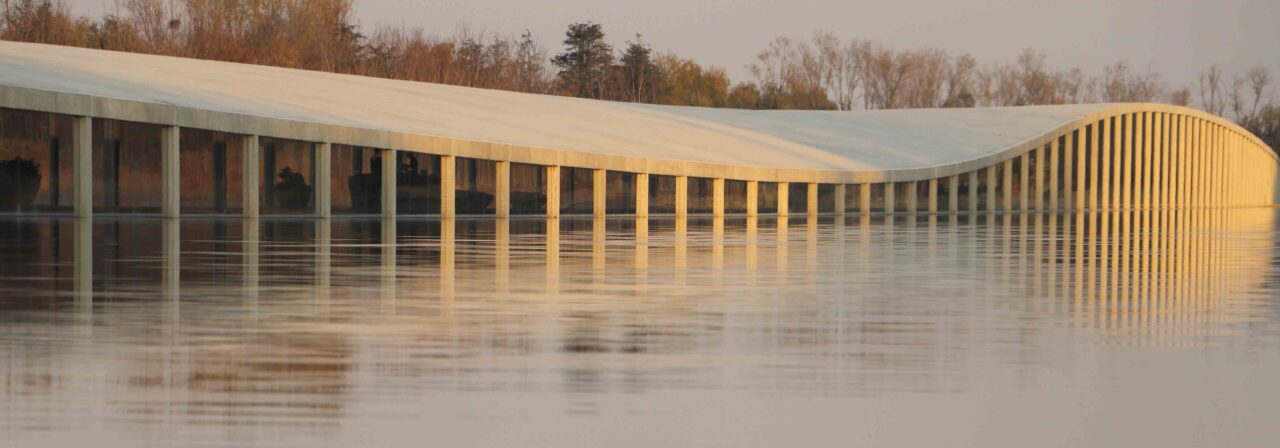

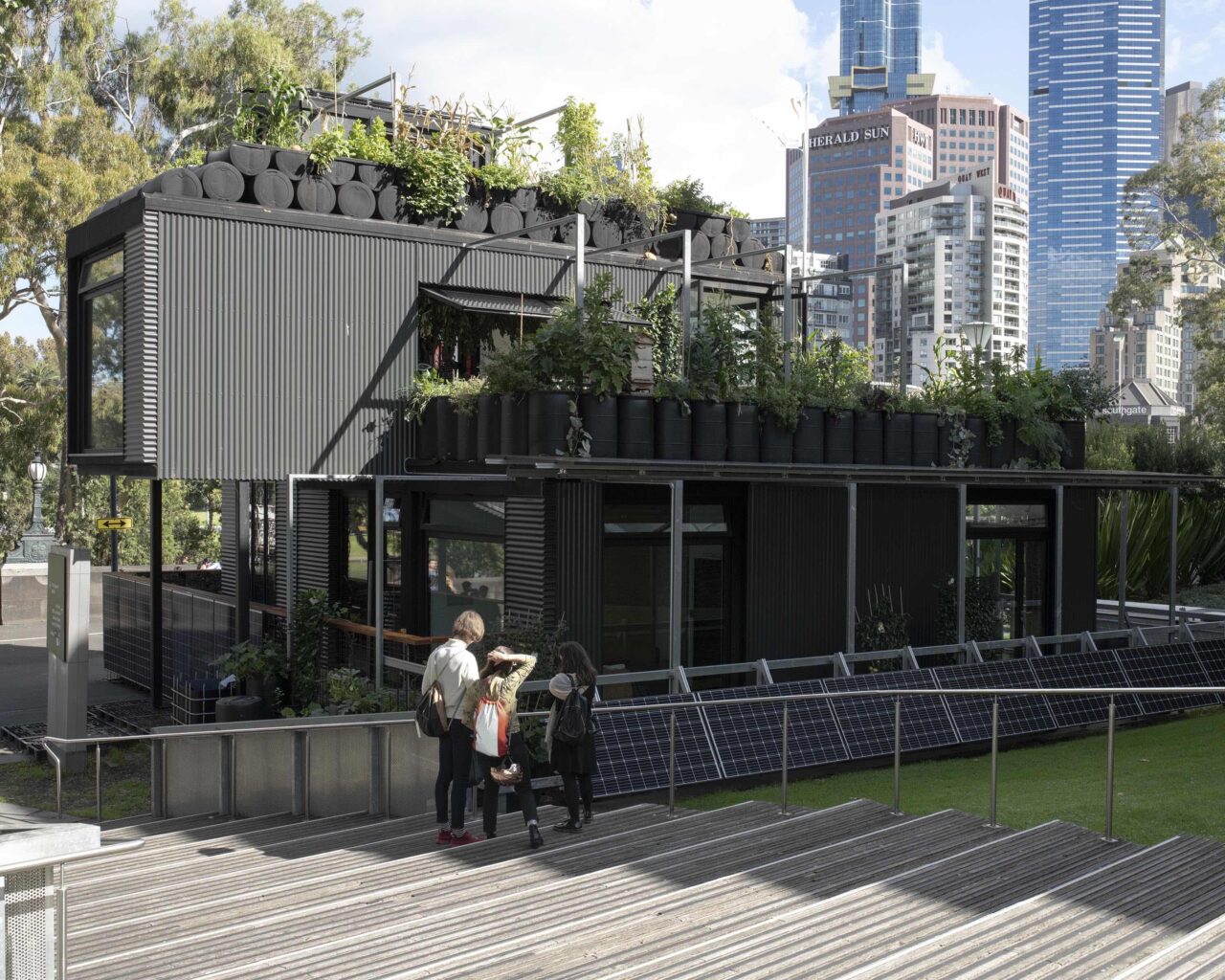

A designed “eco-system that mimics nature”, the Greenhouse is a 3-story living, breathing building made completely with no synthetic materials, operating to a completely circular no-waste rhythm. Twenty-five years in the making, Joost’s vision has brought him to his 5th iteration of the ‘Greenhouse’ here in Fed Square next to the Yarra River in Melbourne central. On the premises, zero-waste chefs Jo Barrett and Matt Stone are permanent residents whilst the house remains on the banks of the Yarra River in Fed Square until it is relocated to Monbulk as a home for Joost’s mother.

Growing everything on the premises, Jo and Matt harvest, eat and cook only what is available to them in the 87-square-metre home operating with a fully circular system – in regard to the building’s materials, water, energy and most importantly for the chefs, produce. Award-winning in their own right and approach to zero-waste cooking, Jo and Matt explore and elevate what is available from the 200 species of plant life in their garden (in addition to a chicken coop, Flow beehive and hydroponics system – more on that later). The focus is on nutrition and seasonal home-grown availability, with Jo and Matt extending their explorations to highlight both modern and ancient preservation and fermentation methods.

“In nature, waste doesn’t exist, it’s only humans that generate waste”, Joost reminds us that we can design waste completely out of our lives. In the Greenhouse, centuries-old building, process and harvesting techniques are found alongside innovative new solutions by entrepreneurs he has come across in all aspects of the industry.

Only useful materials that can have the ability to have a circular lifespan have been utilised in the build. Recycled brass taps, copper for flooring and straw paneling in walls are just some of the beneficial design solutions accompanying rainfall collection and solar paneling for water and energy supply.

The Greenhouse utilises rainfall to water plants, supply the house and support its hydroponic system supporting the growth of yabbies, freshwater mussles, rare golden barramundi and native greens. Inventive yet simple approaches such as harvesting steam from the shower (in addition to condensate from the hot water service) to grow mushrooms is one of our favourites. The steam inoculates the mycelium in recycled tubs and flowers mushrooms with the potential to grow 10-20kg’s per week in the Greenhouse’s Mush Room wall. The mushrooms then create carbon dioxide, which is looped back out into the atrium for plant life. Electricity comes from nickel-iron batteries (which can last for decades and can also be recycled back into their original materials) and gas is created from a biodigester (the Cows Stomach) on the ground floor. Made in Israel especially for the Greenhouse, organic waste (such as plants and human faeces) are fed into the biodigester to create energy used in the kitchen and heating.

The straw walls in the Greenhouse are void of any chemicals, toxins or glues, only compressed, coated in natural lime and embedded with charcoal. This idea came to Joost whilst on his honeymoon in Cuba 20 years ago, when he visited a hospital and noticed bowls of charcoal were used to prevent patients from getting golden staph. Grounding and connecting to the Earth’s magnetic field has also been of ultimate importance to Joost, emphasising the anti-inflammation benefits of this simple concept. To do this, copper wire was laid amongst concrete made with crushed recycled wine bottles instead of sand to ensure it was recyclable. The Greenhouse’s kitchen cabinetry and centrepiece staircase has also been made from a 130-year old Cypress tree struck by lightning in Ballarat, using no timber harvested from mono-culture plantations which are a big problem for the planet. Design solutions are all around us.

Intentionally saving and harvesting materials from our waste stream and repurposing them in building design, these ideas are not provided for in the mainstream, consumerist models of home-building and living, but this conscious approach is becoming more and more urgent in the world we live in. With the Greenhouse, Joost has created a blueprint for the home of the future, ready – and urgently needed – today. With so much of the world destroyed by farming and agriculture, in addition to food over-consumption also ending up in landfill, the Greenhouse highlights that the Future Food System is accessible and achievable by all.

Years of Joost’s research are shared step-by-step on his platform and video stream, with his Greenhouse and Future Food System blueprints open-source. During our guided tour of the Greenhouse, Joost explained some of the key design decisions he made to equate for ultimate sustainability and innovative no-waste systems:

THE BIODIGESTER

Underneath the stairs at the back is a really remarkable bit of a kit. It’s a biodigester, and what it does is smash up any organic waste. It’s fed into a bladder which has got the same biology as a cow’s stomach. Each person on Earth (generates) a kilo of organic waste a day – that’s from the toilet and other organic waste. Each kilo converts to an hour of continuous flame from gas. So the methane that we produce, that has the capacity to produce four hours of energy a day. That’s [just when it’s] four times bigger than a commercial family unit, so HomeBioGas in Israel designed the unit we have especially for our Greenhouse because they were worried that we had so much garden growing that a conventional system wouldn’t be enough.

We’re currently wasting between seven and eight billion hours of potential energy every single day. The bladder transforms organic waste and smells into cow manure, which is highly valuable to plants and really easy for plants to actually absorb nutrients from. What I’ve done is taken it to the next level and I’ve linked it to a WormWorks work bath, so when we transform the material we add even more biology before we put it back on the plants. It’s the same as if you were in a field and lift a cow patty and underneath it’s filled with worms. This is because worms come out of the ground and eat all the nutrients and bring it back down into the ground.

THE MUSH ROOM

When you have a shower, the steam gets pumped directly into the Mush Room to grow our different varieties of mushrooms. The Mush Room actually harvest steam from the shower, and condensate from the water service. There are 20 different types of mushrooms here. Every bucket is made up of fibrous cellulose waste like coffee grounds, corn stalks, cardboard and newspaper. I’ve designed the Mush Room this size so it can specifically utilise the same waste amount that a normal Australian household currently uses.

The hot water system is metres away from the showerhead, so when you turn the hot water tap on it takes about two seconds to get hot water. It is 2.6 metres away from the tap in the kitchen, so I’ve designed this so that there is minimal energy use and loss of hot water. We also use a condensate; every single hot water unit in the world uses a condensate, so you can imagine how much water’s going down the drain, with a family of five using about 20 litres. That is more than enough to keep the mushrooms at the right humidity. It is actually remarkable how quickly they grow.

MATERIALS AND STRAW PANELLING

The bedrooms are made with straw panels. They’re straw – Stramit – boards since 1954. Fifty-year-old panels.

Straw is the world’s most wasted resource. Nothing comes close. No plastic; there’s no other wasted resource that exists that’s more abundant than straw. Every kilo of grain, oats, wheat, barley, rye produces a kilo of straw on average. What we’ve done over the last 50 years, we’ve reduced the height of crops to stop them from blowing over, so the straw has come down, but we’re still producing the same amount of straw.

Straw papyrus – the word paper comes from papyrus – which is the grass the world’s first paper was made from. We should be using straw to make cardboard and paper because it takes a lot less energy and a lot less chemicals to make paper and cardboard from straw. Sadly, though, we use wood chips to make toilet paper and cardboard, like the Victorian Government sells, which is a dollar a ton. So farmers will never ever be able to compete with that which is heavily subsidised … It’s insanity when you think about, some of those trees are 355 years old and are turned into wood chips for toilet paper and takeaway packaging. India, mainly because they’ve cut all their trees down, but have now set up factories that turn farm waste into paper and cardboard made in huge paper mills. (I don’t know if anyone remembers Nature’s Paper from India made from straw, you used to be able to get it from Office Works right here in Australia).

This straw panelling here is made in Bendigo by Durra Panel. It used to be made all over the world, but all the factories shut down apart from one, and that was in Bendigo. A lot of their export was to Europe because in Europe, they regard it as the most sustainable building material in the world. Now, Dura Panel are not interested in exporting it overseas, they’re interested in exporting the idea because there’s no point logistically – there’s tons of old durum wheat being grown and rice in Italy, China, everywhere… These factories need to be in the middle of where all these crops are being grown. A decision by the Chinese government last year to ban the burning of straw stubble did more for the environment than any decision by any government in the last 30 years, I believe. If you think about the 100 million farmers in China that were burning straw, sometimes three times a year, getting three crops a year, the emissions are massive. There’s a huge drive in China to find alternative solutions to straw because the farmers are wondering what they should do with it. So it’s a really exciting space.

I’m proud of the fact that I haven’t used any FSC-certified timber here in the Greenhouse. The Forest Stewardship Council was started in 1992 with Greenpeace and World Wildlife Fund for good reason, to give us confidence that when we buy a roll of toilet paper, paper, book, piece of furniture or timber for our house, we know that that wood hasn’t come from the Amazon.

With over a billion (hectares) of wild, biodiverse, old growth forest cut down since the foundation of FSC in 1992, it’s become clear protection of forests is non existent and it’s fair to say ancient forests are being cleared at the fastest rate in history (419 million hectares in 2019). Frustratingly, the carbon credits that we pay when we fly or get our green energy are actually going towards paying these companies to replant the old grove forests that they’ve just taken down. It’s a single-species monoculture. Alot of architects say this is crazy, because wood is the most stable choice because it absorbs carbon. The first thing I say is that you should go for a walk in a single-species monoculture forest and you’ll walk out and you’ll understand why this idea is not sustainable. I’m a huge fan and believer and supporter of agroforestry, if our farmers in Australia planted just ten trees each a year, we’d be totally self-sufficient in timber in 15 years’ time. If they planted 20, we’d be a massive exporter.

There’s a great farm – Yan Yan Gurt Farm in Deans Marsh – who planted 40,000 trees in the last 28 years and created these beautiful wildlife corridors. They totally turned around their farm and have four generations of people working on there now and they’re completely profitable. They’ve created wind protection for the sheep, created pockets of biodiversity with 250 different species of trees. That’s a great model going forward. I believe that our farmers hold the solution. So we can stop clearing land, stop logging wild land, wild species, and then stop planting monocultures.

GROUNDING TO THE EARTH’S MAGNETIC FIELD

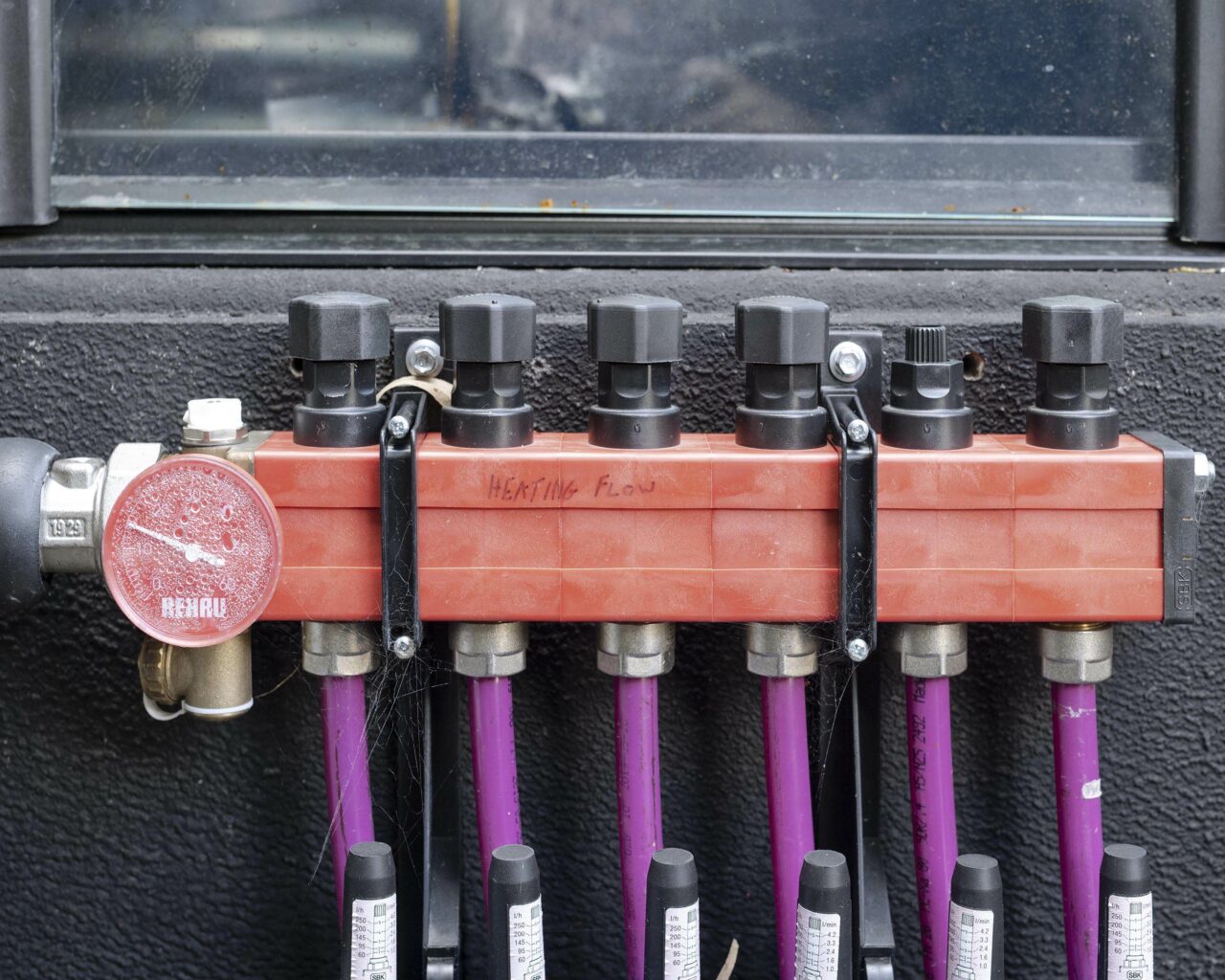

The reason why I wanted concrete [on the flooring] was because this is an Earthing floor. I want my mum to be able to walk bare feet in this house to get around, so that means that the floor has to be heated in winter and cool in the summer. We use a heat pump, and solar power to generate hot water for heating the floor, and it’s a great conductor. If your feet are warm, you feel warm. So the air can be much cooler, but as long as your feet are warm.. The main reason for bare feet is that you’re grounded, you’re connected to the Earth’s magnetic field. Two friends of mine, filmmakers Josh and Rebecca Tickell, made a film called The Earthing Movie about four years ago, about Clint Ober who actually discovered the immeasurable benefits of grounding and that inflammation can’t exist in the human body when it’s Earthed. It just can’t happen. So when you think about inflammation, that’s causing pretty much a lot of ailments (such as acne, cancer..).

Jo who lives here, sleeps on a grounding blanket – her period pain is gone after starting to sleep on grounding blankets. It is like a sheet but it has woven stainless steel through it. My kids and I also also sleep with grounding blankets. My wife, when she types, she has a grounding sheet in front of her keyboard, and my father-in-law sleeps on a mat as well. There’s lots of stuff. But the film is awesome.

What I love about this idea is that you don’t need to go and buy something really expensive. You can just take your shoes off and go for a walk on the beach. Wet grass is a really good conductor. Asphalt doesn’t conduct so there’s no point walking bare feet on asphalt. Concrete’s great, stone’s great. So that’s the reason why I’ve done this floor the way that I have. Had some brilliant Portuguese tilers that were here watching me run around with my meter going in bare feet saying “Oh no, I’m zero here”, because I’ve got a meter that actually says whether I’m conducting or not. They’re just scratching their heads thinking this is the strangest thing they’ve ever seen.

COPPER WIRE AND RECYCLED CONCRETE

We laid copper wire in where the grout is between the tiles so we can connect to the Earth’s magnetic field.

These tiles are made from recycled concrete and recycled glass – I’ve worked with a company called Concreters Collaborative, run by a guy called John, who is semi-retired but he spends his whole life in concrete. For the concrete, he worked out how they can replace sand with recycled glass bottles. The most important part is, the tiles can be recycled at the end of their life.

HYDROSYSTEM

The aim is to create a biology that you would have when you walk into a rainforest. You know how good you feel when you walk through an old (growth) forest, it’s because of the air that you breathe is filled with so many different species of bacteria and micro fungi. That’s what makes you feel so good. By having half a dozen different species of fish and freshwater mussels and yabbies I’m trying to recreate that in this house. When you walk up the stairs each morning, you can smell the system.

The uptake as Barramundi fish as an aquaponics species is quicker than any other. Here we have a rare Golden Barramundi growing, it is the ultimate species for micro-systems. We believe that where we generate food waste, is where we should be producing fish, because that food waste can be turned into fish food. That fish food then becomes nutrients for all the plants in the house. We use a Thermomix for grinding the fish waste. It’s mixed in with freshly-foraged seaweed, adding greens, an egg, offcuts of stalks, crickets… Freeze it then grate it. We’re experimenting with all different types of recipes. It’s insane to think that 40% of the worlds fish are fished to feed fish. At the moment it takes 4kg’s of wild fish to feed 1kg of farmed fish. We’re destroying the ocean to create what people perceive to be sustainable.

THE IMPORTANCE OF GOOD SOIL

I’m all about biology and biodiversity, creating the most biodiverse soil that we can possibly have.

Soil that contains mycelium and worms produce a micro flora or a bacteria that’s called Mycobacterium vaccae, and that’s just one of the beneficial bacteria. We’re talking about one worm with even billion bacteria in its gut, on average. We do know is that Mycobacterium vaccae is really good for our brain. When it’s fed to rats in a test, the rats navigated a maze in half the time and their heart rate was half of rats that didn’t have it in there. So I’m a big believer that our food relies on good soil with worms in the system.

Words Monique Kawecki Champ Editor In Chief | Images Dan Bushaway